An ounce of prevention is worth far more than a pound of cure. Especially in the winter when we’re talking truck maintenance.

Those emergencies on the road can destroy any profit from a load. We can’t predict when a part is going to fail. Debris on the road can cut a tire. A rock can break a windshield. The unexpected breakdown hurts far less than the ones we know could have been prevented with regular maintenance.

Oil changes. Transmission fluid. Brake fluid. Even window wiper blades. It can mess up everything – one blown gasket, one busted fuel pump. Your truck could be out of commission for only hours – or for days.

Having a good mechanic is critical. Whether it’s someone who just graduated who’s up on all the latest technical details or the guy that’s older than the hills three miles from the highway in your hometown, you need someone who knows your rig.

What Should Truck Maintenance Management Cover?

The Department of Transportation has a checklist of 13 items.

|

|

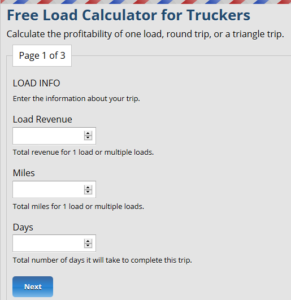

There are dozens of forms available on the Internet of the DOT inspection list that any mechanic could download and use. But the mechanic will also have to track a truck’s mileage to check on tires, brakes, and the fuel system. Most mechanics don’t have access to the truck’s mileage records to know when an inspection ought to be scheduled until the truck pulls in – often past the due time. This is what can lead to on the road breakdowns or emergency repairs, or failure to pass a CVSA inspection. Truck maintenance management, when done correctly, can save an owner-operator or a trucking business thousands of dollars.

How to track your truck’s maintenance

Many maintenance tune-ups and check-ups are based on time or miles. You can be a thousand miles from your usual mechanic when you need a scheduled oil change or the brakes inspected. Is it worth it to get it done by a mechanic you don’t know while you’re on the road?

I don’t think so. A little leeway in getting a check done if there isn’t a sign of problems won’t likely lead to an emergency (knocking on wood as I say that.) But making maintenance a priority – even over a load – to prevent a breakdown is smart planning.

Calendars and Mileage

A calendar can keep track of monthly or annual inspections, but the ones that depend on the miles driven can catch you by surprise. That’s why TruckingOffice’s maintenance module is so useful. Keeping track of your truck’s mileage is pretty simple with a program that’s creating your truck’s routes for loads. No extra data entry is needed for TruckingOffice to notify you that your truck needs an oil change. If you have more than one truck, our truck maintenance software will alert you every time one of your vehicles is due for scheduled maintenance.

This is essential for ensuring both your safety and that of your drivers. With TruckingOffice’s web-based platform and low monthly fee, you’ll save money and enjoy new levels of convenience and peace of mind at the same time.

Of course, even with the best truck maintenance software, you should know how to perform a basic safety inspection. With that in mind, here’s a review of the basics. Think of this as a handy brush-up on the things every driving pro know.

Truck Maintenance Safety Checklist

- Make sure the cab floor is free of rags, towels, food containers, tools, and other items that may block smooth pedal operation.

- Ensure that the safety belts work properly and are free of nicks, tears, or other signs of wear or damage.

- Make sure that all gauges, heaters, wipers, defrosters, turn signals, and other instruments function properly.

- Ensure that the vehicle has emergency equipment such as flares, reflective triangles, and a fire extinguisher on hand. Make sure the extinguisher is within the expiration date and the operation instructions are clearly displayed.

- Check headlights, exterior turn signals, running lights, and reflectors. Replace as necessary.

- Make sure the tires are properly inflated. Check for worn tread, blemishes, and other warning signs.

- Make sure every vehicle has the required records, including maintenance information, and if the truck is leased, the name of the leaser.

- Check the brake couplings and other components to ensure they are properly attached.

- Make sure all required placards, including hazmat notices, are in place and easily visible.

By following the above guidelines, you can help to ensure that every trip is both safe and profitable. And remember: for the best truck maintenance software in the business, nobody beats TruckingOffice. Find out for yourself by taking our product for a free test drive starting today.

Recent Comments